AX5 SNG Vaporizer / Propane-Air Mixer (NG backup system)

- Electric

- Hot water

- Steam

- Electric Waterbath type

- Capacity : 200 – 750 kg/h

- External Control Panel

- Float Valve safety feature (200 / 300 / 500 kg/h models)

*Our Patented Technology - Thermo Valve safety feature (EVM-750AX5)

- Explosion-proof : Flameproof / Intrinsic safety

- Ex d ia II B T4 Gb / Class-1, Division-1

Idioma : English / Español

SNG Vaporizer / Propane-Air Mixer

Natural Gas backup system

- NG BACK-UP: Solution for piped natural gas supply troubles.

- SNG (Synthetic Natural Gas) GENERATION: Propane-Air synthetic gas to substitute natural gas.

- SUITABLE FOR: places where NG supply is not stable. Also useful for peak-shaving solution.

- SPACE SAVING: AX5 LPG vaporizer and mixing unit is compactly packaged on skid.

- CHOICES: Standard models and High pressure models available upon requirements (200-750kg/h).

Introduction of Kagla’s SNG system

(SNG vaporizer / Propane-Air mixer)

Necessity of back up system for Natural Gas

Securing a backup line is very important for any type of energy supply.

For example, in the manufacturing industry, if the energy supply is cut off, the production line will be stopped, causing serious damage to corporate activities.

As for electricity, a backup generator is essential to prepare for an unexpected power outage.

In the case of LPG that you store in the tanks or cylinders at your own facility, if you create a bypass line for natural vaporization separately from the vaporizer, you can prevent the problem of gas supply interruption.

Now what if the supply of piped natural gas is cut off?

Solution for Natural Gas supply problem

SNG Vaporizer / mixer / blender is a backup system that protects your business in the event of a natural gas supply problem.

SNG is a mixed gas of LPG and air. And thus often this type of system are also called Propane-Air mixer.

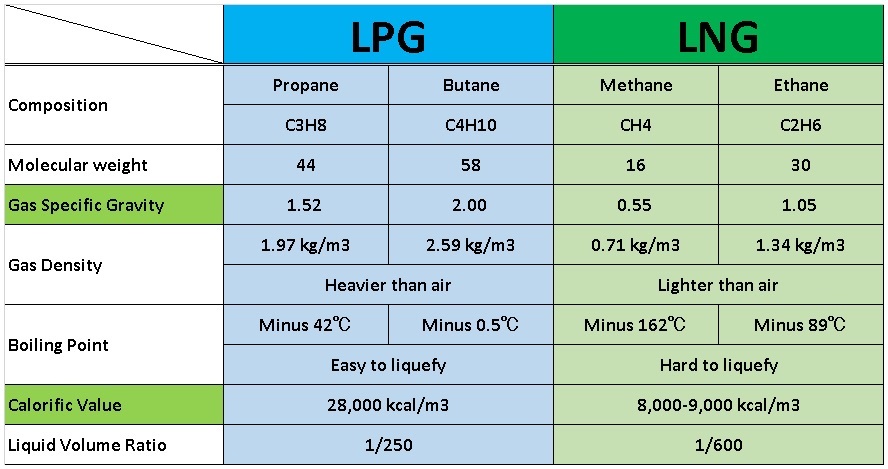

If you refer to the list below, you will see that LPG and NG are gases with different combustion characteristics.

All values such as calorific value, specific gravity, boiling point, etc. are different.

Since the combustion speed is also different, ordinary combustion equipment for NG cannot be operated with LPG as is.

Differences and similarities between LPG and NG:

However, if you compare the chemical formulas of LPG (propane/butane) and NG (methane/ethane), you will see that both are composed of carbon and hydrogen.

SNG vaporizer (Propane-Air mixer) was developed based on this similarity. This system dilutes LPG with air to produce synthesis gas that has combustion characteristics similar to NG.

This Propane-Air mixed gas produced by this equipment is called SNG (Synthetic Natural Gas), and can be used as a backup fuel that can be used with NG combustion equipment.

Natural gas, which is difficult to liquefy and store, is supplied in vapor state through piping, so it is almost impossible to prepare your own backup natural gas.

On the other hand, with an SNG system that generates synthetic gas from LPG and air, by installing your own LPG storage tank in each facility, gas supply can be continued without stopping the equipment.

It is a useful backup system to substitute natural gas in case you have trouble with natural gas.

Calculation of Prppane-Air mixing rate : Wobbe Index to specify matching system

Several factors must be considered when calculating the appropriate propane-air mix ratio for SNG.

Would it be enough to simply adjust the calorific value of mixed gas to be the same with that of Natural Gas by diluting with air?.

Unfortunately, it is not so simple.

To generate a mixed gas that can substitute NG, it is necessary not only to adjust the calorific value to be close to that of NG, but also to use a calculation formula that takes into account the specific gravity and combustion speed of the mixed gas.

The Wobbe Index (WI) is a guide for this calculation.

This is a bit complicated… Yet you don’t need to panic.

KAGLA will do this calculation to specify the matching SNG system to satisfy your requirements.

You can also refer our calculation page on our website for easy guidance

Link : Calculation to find matching SNG mixer

Applications of SNG backup system : where the system will be used

SNG systems are used as back up for Natural gas in various cases. Below are some of the cases our SNG systems are installed.

Tentative measurement until natural gas is supplied

At the facilities such as factories in areas where natural gas will be supplied in the future, KAGLA backup mixer can be a tentative measurement until natural gas supply pipelines would be constructed.

You can utilize your combustion equipment without any changes once natural gas would be available in the area.

Backing up your natural gas supply system

When there is the shortage or insufficient pressures of natural gas, KAGLA backup mixer solves these problems by substituting natural gas supply.

Alternative fuel when natural gas prices fluctuate

When fuel price fluctuates rapidly and LPG price becomes lower than natural gas, KAGLA backup mixer can be your alternative solution in order to save your fuel cost.

Peak shaving purpose

For users who purchase natural gas on a metered basis, a temporary increase in gas consumption during the peak business season is troublesome. In many cases, excess natural gas will be purchased at a higher price.

If you are about to exceed your contracted usage limit, you can save costs by switching gas consumption that could exceed your monthly usage cap to SNG.

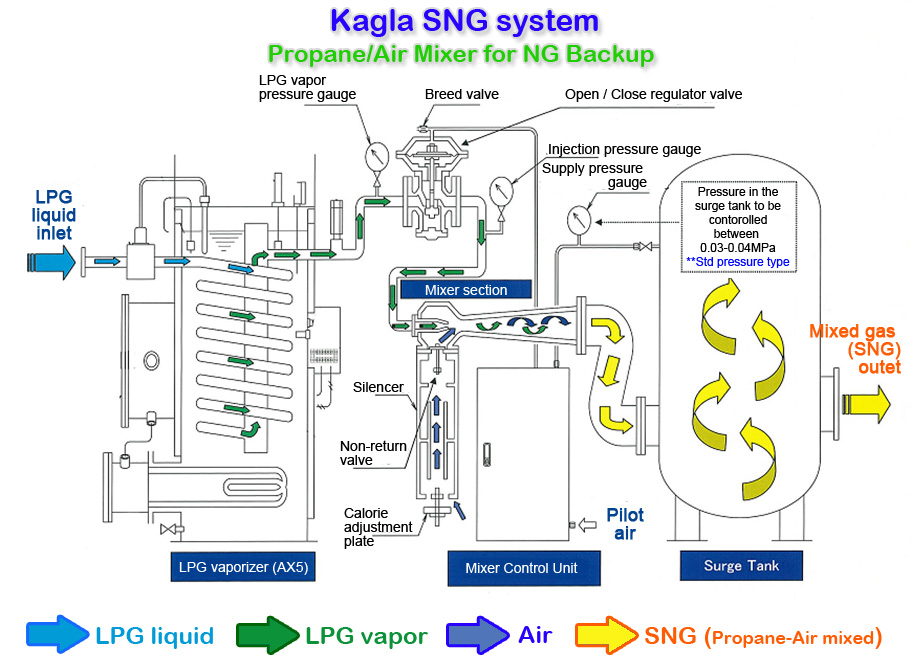

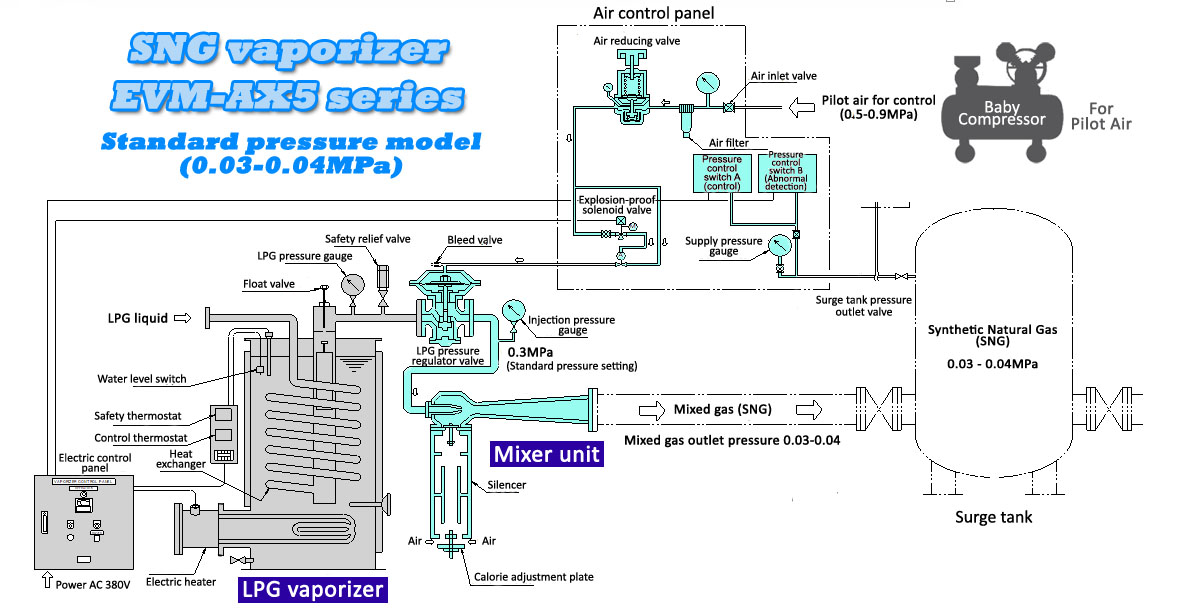

Kagla SNG system : EVM-AX5 series

Kagla’s SNG system is compactly packaged on a skid that combines an LPG vaporizer with an air mixing device.

The vaporizer section is equipped with Kagla AX5vaporizer that has been modified specifically for the SNG system.

Of course, an external control panel is also included.

The mixer section plays a crucial role in generating SNG and employs a Venturi design.

Within the tapered venturi pipe, the flow velocity of LPG vapor and air increases, ensuring an even mixture.

The generated SNG is stored in a surge tank and the gas is consumed from there.

As gas (SNG) is consumed and the pressure in the surge tank drops, LPG vapor is introduced into the mixer section from the AX5 vaporizer.

Air is drawn in only during the injection of LPG vapor, ensuring safety by preventing the formation of syngas with a dangerous mixture ratio within the explosive range.

By having this SNG system, even if a problem occurs in the supply of NG, the operation is automatically switched to Kagla SNG system by sensing the pressure drop in the NG piping.

And thus you can continue operation without stopping the equipment.

There are various capacity choices and standard / high pressure models for each.

Flow Sheet and mechanism

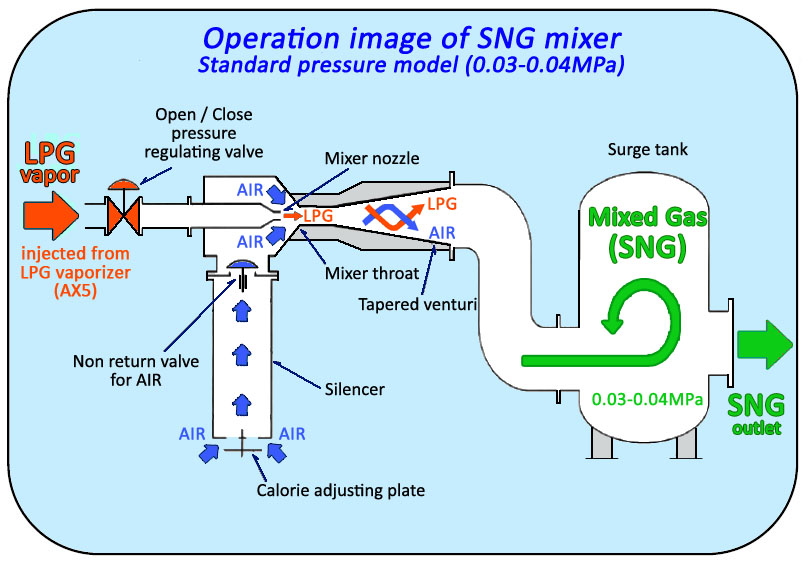

HOW SNG SYSTEM WORKS : Standard pressure model

System component equipment

Kagla SNG system

LPG vaporizer + mixer unit on skid

Air compressor

For pilot air to open / close the valves

Surge tank

To store mixed gas for mixture and supply

Kagla SNG system (standard pressure model) is a device to inject LPG from vaporizer into mixing part and mix it with air.

Generated mixed gas (SNG) is stored in the surge tank and the gas will be consumed from there.

And the surge tank pressure is always monitored to control SNG generation.

When mixed gas pressure inside the surge tank drops lower than the set value (0.03MPa) by consumption, the mixer control section open the valve at the vapor outlet of the vaporizer by the pilot air from the air compressor. And then LPG vapor is injected through mixer nozzle with high velocity.

This energy created by LP gas injection makes air taken into the mixer unit through air inlet, and LPG-air mixed gas is generated in the tapered venturi pipe.

Generated mixed gas is sent to the surge tank and stored.

Once the pressure inside the surge tank reaches the set value (0.04MPa), the Open/Close pressure regulator valve closes in order to suspend LPG injection.

The LPG pressure regulator valve repeatedly opens and closes for SNG generation as gas is consumed and the surge tank pressure will be kept in the range between 0.03-0.04MPa

As air inlet valve opens only when the LPG is injected, the Kagla SNG system never generate mixed gas with a mixing ratio in the explosive range and thus it can be operated safe and stable.

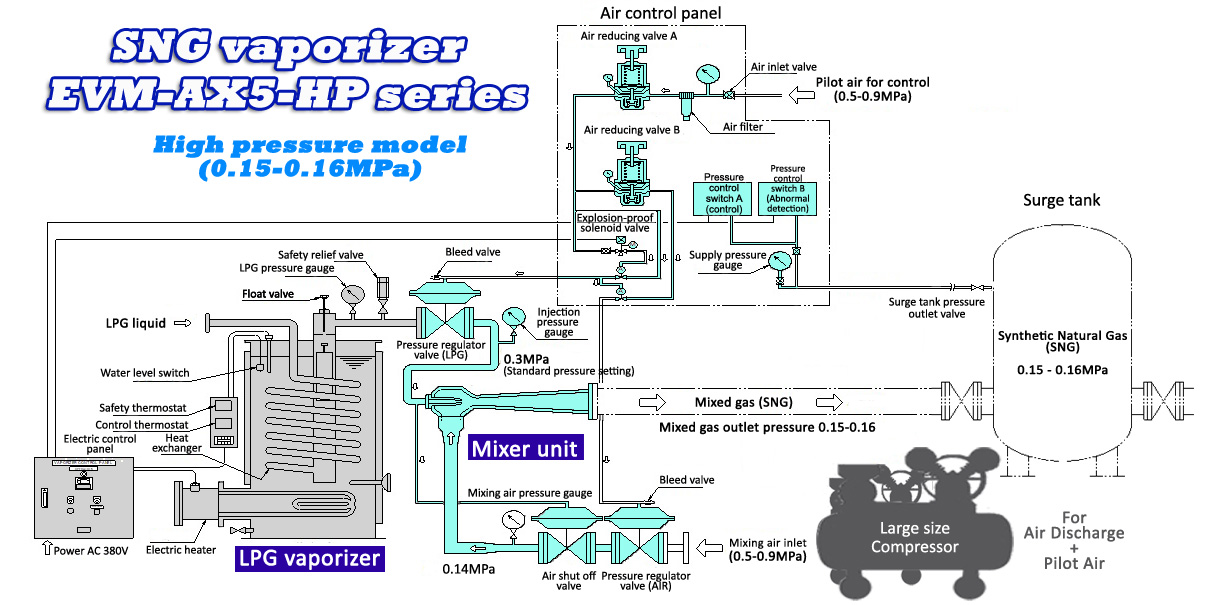

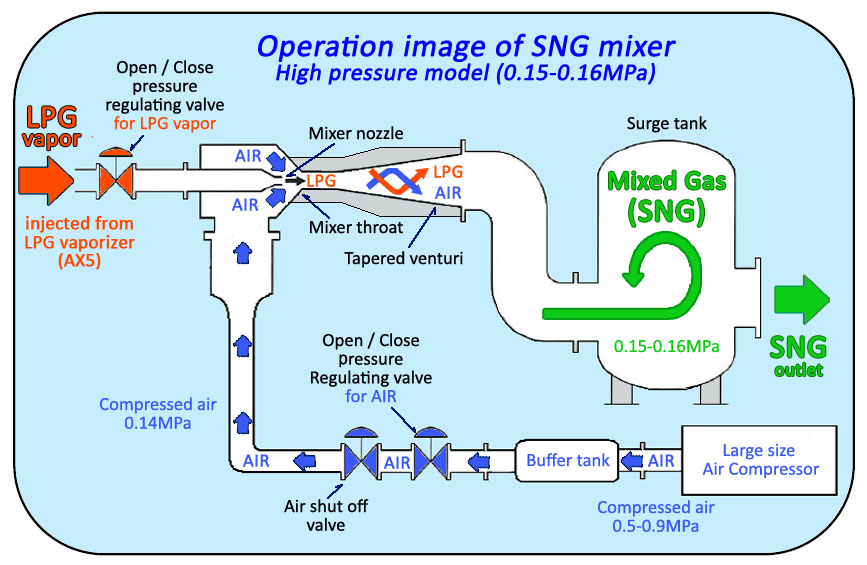

HOW SNG SYSTEM WORKS : High pressure model

System component equipment

Kagla SNG system

LPG vaporizer + mixer unit on skid

Air compressor

For pilot air to open / close the valves

For supply of compressed air to mix with LPG vapor

Surge tank

To store mixed gas for mixture and supply

Kagla SNG system (high pressure model) is a device to inject LPG from vaporizer into mixing part and mix it with air.

Generated mixed gas (SNG) is stored in the surge tank and the gas will be consumed from there.

And the surge tank pressure is always monitored to control SNG generation.

Therefore, the basic structure and function is the same with the standard pressure model.

The difference is that compressed air is supplied from air compressor to attain high pressure SNG (0.15-0.16MPa).

Of course the additional devices to control compressed air is equipped.

When mixed gas pressure inside the surge tank drops lower than the set value (0.15MPa) by consumption, the mixer control section open the valve at the vapor outlet of the vaporizer and also the compressed air inlet valve by the pilot air from the air compressor.

Then both the LPG vapor and compressed air is injected with high velocity. And LPG-air mixed gas is generated in the tapered venturi pipe.

Generated mixed gas is sent to the surge tank and stored. Once the pressure inside the surge tank reaches the set value (0.16MPa), the Open/Close pressure regulator valve closes in order to suspend LPG injection.

Air shutoff valve is mounted as a safety device on air supply line.

The air shutoff valve opens and closes by directly receiving LPG injection signal so that no air is injected unless LPG is injected into the mixer unit.

Therefore, the Kagla SNG system never generate mixed gas with a mixing ratio in the explosive range and thus it can be operated safe and stable.

Features

ADVANCED SAFETY MECHANISM

USER FRIENDLY INTERFACE

SPACE SAVING COMPACT BODY

EASY MAINTENANCE STRUCTURE

DRAINAGE MEASURE

As for features and function, please refer following pages of AX5 LPG vaporizers.

For EVM-200/300/500AX5 : AX5 LPG vaporizers

For EVM-750AX5 : 750/1000AX5 LPG vaporizers

Specification

| Standard model specification | ||||||

|---|---|---|---|---|---|---|

| MODEL | EVM-200AX5 | EVM-300AX5 | EVM-500AX5 | EVM-750AX5 | ||

| Gas | LPG (Liquefied Petroleum Gas) for SNG generation | |||||

| Vaporization Capacity (kg/h) | 200 | 300 | 500 | 750 | ||

| Mixed Gas Spec | Supply Volume (Nm3/h) | 160 | 240 | 400 | 600 | |

| Supply Pressure | 3000~4000 (mmAq) | |||||

| {30~40 (kPa)} | ||||||

| Calorie | 58.0 ~ 63.0 (MJ/Nm3) *1 | |||||

| {13850 ~ 15000 (kcal/Nm3)} | ||||||

| Wobbe Index (WI) | 48.6 ~ 52.2 (MJ/Nm3) *1 | |||||

| {11620 ~ 12470 (kcal/Nm3)} | ||||||

| Reference NG Calorie | 39.2 ~ 42.1 (MJ/Nm3) *1 | |||||

| {9400 ~ 10000 (kcal/Nm3)} | ||||||

| Electric Heater (kW) | 28 | 42 | 63 | 96 | ||

| (14kW x 2) | (21kW x 2) | (21kW x 3) | (32kW x 3) | |||

| Standard: 3Phase 380V *2 | ||||||

| Electric Control Panel | Size (mm) | 450 x 500 x 250 | 550 x 600 x 250 | |||

| Width x Height x Depth | ||||||

| Weight | 15 | 25 | ||||

| Power | Single Phase AC220V (±10%) 50/60Hz | |||||

| Connection Bore | LPG Liquid Inlet | JIS 20K 20A | JIS 20K 25A | |||

| Mixed Gas Outlet | JIS 10K 80A | JIS 10K 100A | JIS 10K 125A | JIS 10K 150A | ||

| External Dimensions | Width (mm) | 1150 | 1300 | 1850 | ||

| Height (mm) | 1700 | 1800 | 2200 | 2500 | ||

| Depth (mm) | 1150 | 1300 | 1600 | |||

| Weight (kg) | 600 | 700 | 800 | 1600 | ||

| Required Surge Tank Capacity (m3) | More than 5.0 | More than 5.0 | More than 12.5 | More than 19 | ||

| Mixer Panel | Control Air | Pressure | 0.5 ~ 0.9 | |||

| (MPa) | ||||||

| Required Air (Nl/min) | 50 | |||||

| Power | Single Phase AC220V (±10%) 50/60Hz | |||||

| Accessories | Electric Control Panel, Anti-Corrosive Solution, Anchors, and Installation, Operation and Maintenance Manual | |||||

*1 Reference value in case of NG specific gravity 0.65

*2 Other Power Voltage available 200 ~ 460V

*3 Figures show on the table are approximate. Specifications are subject to change without notice.

| High pressure model specification | ||||||

|---|---|---|---|---|---|---|

| MODEL | EVM- | EVM- | EVM- | EVM- | ||

| 200AX5-HP | 300AX5-HP | 500AX5-HP | 750AX5-HP | |||

| Gas | LPG (Liquefied Petroleum Gas) for SNG generation | |||||

| Vaporization Capacity (kg/h) | 200 | 300 | 500 | 750 | ||

| Mixed Gas Spec | Supply Volume (Nm3/h) | 160 | 240 | 400 | 600 | |

| Supply Pressure | 15000~16000 (mmAq) | |||||

| {150~160 (kPa)} | ||||||

| Calorie | 58.0 ~ 63.0 (MJ/Nm3) *1 | |||||

| {13850 ~ 15000 (kcal/Nm3)} | ||||||

| Wobbe Index (WI) | 48.6 ~ 52.2 (MJ/Nm3) *1 | |||||

| {11620 ~ 12470 (kcal/Nm3)} | ||||||

| Reference NG Calorie | 39.2 ~ 42.1 (MJ/Nm3) *1 | |||||

| {9400 ~ 10000 (kcal/Nm3)} | ||||||

| Electric Heater (kW) | 28 | 42 | 63 | 96 | ||

| (14kW x 2) | (21kW x 2) | (21kW x 3) | (32kW x 3) | |||

| Standard: 3Phase 380V *2 | ||||||

| Electric Control Panel | Size (mm) | 450 x 500 x 250 | 550 x 600 x 250 | |||

| Width x Height x Depth | ||||||

| Weight | 15 | 25 | ||||

| Power | Single Phase AC220V (±10%) 50/60Hz | |||||

| Connection Bore | LPG Liquid Inlet | JIS 20K 20A | JIS 20K 25A | |||

| Mixed Gas Outlet | JIS 10K 80A | JIS 10K 100A | JIS 10K 125A | JIS 10K 150A | ||

| External Dimensions | Width (mm) | 1400 | 1550 | 2100 | ||

| Height (mm) | 1700 | 1800 | 2200 | 2500 | ||

| Depth (mm) | 1150 | 1300 | 1600 | |||

| Weight (kg) | 800 | 900 | 1000 | 1850 | ||

| Required Surge Tank Capacity (m3) | More than 5.0 | More than 7.5 | More than 12.5 | More than 19 | ||

| Mixer Panel | Control Air | Pressure | 0.5 ~ 0.9 | |||

| (MPa) | ||||||

| Required Air (Nl/min) | 50 | |||||

| Power | Single Phase AC220V (±10%) 50/60Hz | |||||

| Air Compressor for mixing gas supply | Discharge Pressure (MPa) | 0.5 ~ 0.9 | ||||

| Dischage Air Volume (m3/min) | More than 2.4 | More than 3.6 | More than 6.0 | More than 9.0 | ||

| Accessories | Electric Control Panel, Anti-Corrosive Solution, Anchors, and Installation, Operation and Maintenance Manual | |||||

*1 Reference value in case of NG specific gravity 0.65

*2 Other Power Voltage available 200 ~ 460V

*3 Figures show on the table are approximate. Specifications are subject to change without notice.

Download

Contact us

Product inquiry

For inquiries about products and services, please use the inquiry form.