Features

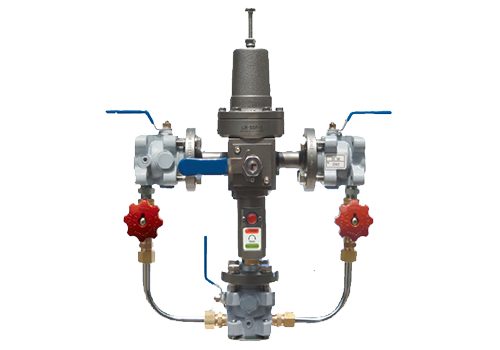

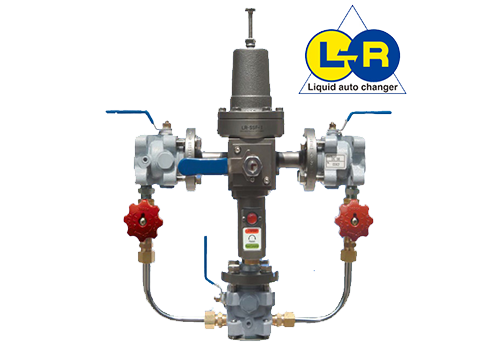

LR unit is a complete set of Liquid Changeover with bypass line pre-installed.

LR / Pureflow (Ball valve with built-in strainer) / piping.

Designed in Compact size for easy installation.

COMPACT SIZE

EASY MAINTENANCE STRUCTURE

Maintenance could be done without stopping the supply of LP gas.

OPTIONAL SCALABILITY

Remote Control of Change signal can be carried out using an explosion-proof lead switch and LR panel.

DOUBLE INDICATORS

Simple structure allows disassembly and assembly to be performed easily at the site.

Specification

| MODEL | LRU-SSF-Ⅰ Features/ LRU-SSF-Ⅱ | ||||||

|---|---|---|---|---|---|---|---|

| Fluid | LPG (Liquefied Petroleum Gas) | ||||||

| Capacity (kg/h) | Max. 300 (100% for propane) | ||||||

| Max. 150 (30% or less for propane) | |||||||

| Changeover Pressure (MPa) | LR-SF-Ⅰ: 0.05 ∼ 0.22 | ||||||

| LR-SF-Ⅱ: 0.15 ∼ 0.34 | |||||||

| Changeover Pressure Operating Accuracy (MPa) | ±0.01 | ||||||

| Required Inlet Pressure | (Changeover pressure +ΔP) ∼ 1.56 MPa | ||||||

| Capacity (kg/h) | 100 | 150 | 200 | 250 | 300 | ||

| ΔP | Type Ⅰ | 0.03 | 0.07 | 0.11 | 0.14 | 0.18 | |

| (MPa) | Type Ⅱ | 0.06 | 0.08 | 0.11 | 0.15 | 0.18 | |

| Inlet Size | JIS20K 20A Flange | ||||||

| Outlet Size | JIS20K 20A Flange | ||||||

| Weight (kg) | 13 | 20 | |||||

| Dimensions (mm) | 215 ×425 ×195 | 385 ×510 ×195 | |||||

| (W×H×D) | |||||||

| LR Panel (Option) | Dimensions (mm) | 90 ×170 ×60 | |||||

| (W×H×D) | |||||||

| Voltage | AC100V | ||||||

| Alarm Terminal | 100V 5A | ||||||

| (Contact material: silver contact plated with gold) | |||||||

Attenttion

- Explosion-proof Signal Transmitter Switch (Optional)

With Signal Transmitter Switch, the actuation of LR could be verified under remote monitor through a telephone line

Control circuit : 220V - LPG consumption should be lower than the LR standard capacity indicated above

- If the LR inlet pressure requirement could not be adapted, it might be necessary to change the LPG composition

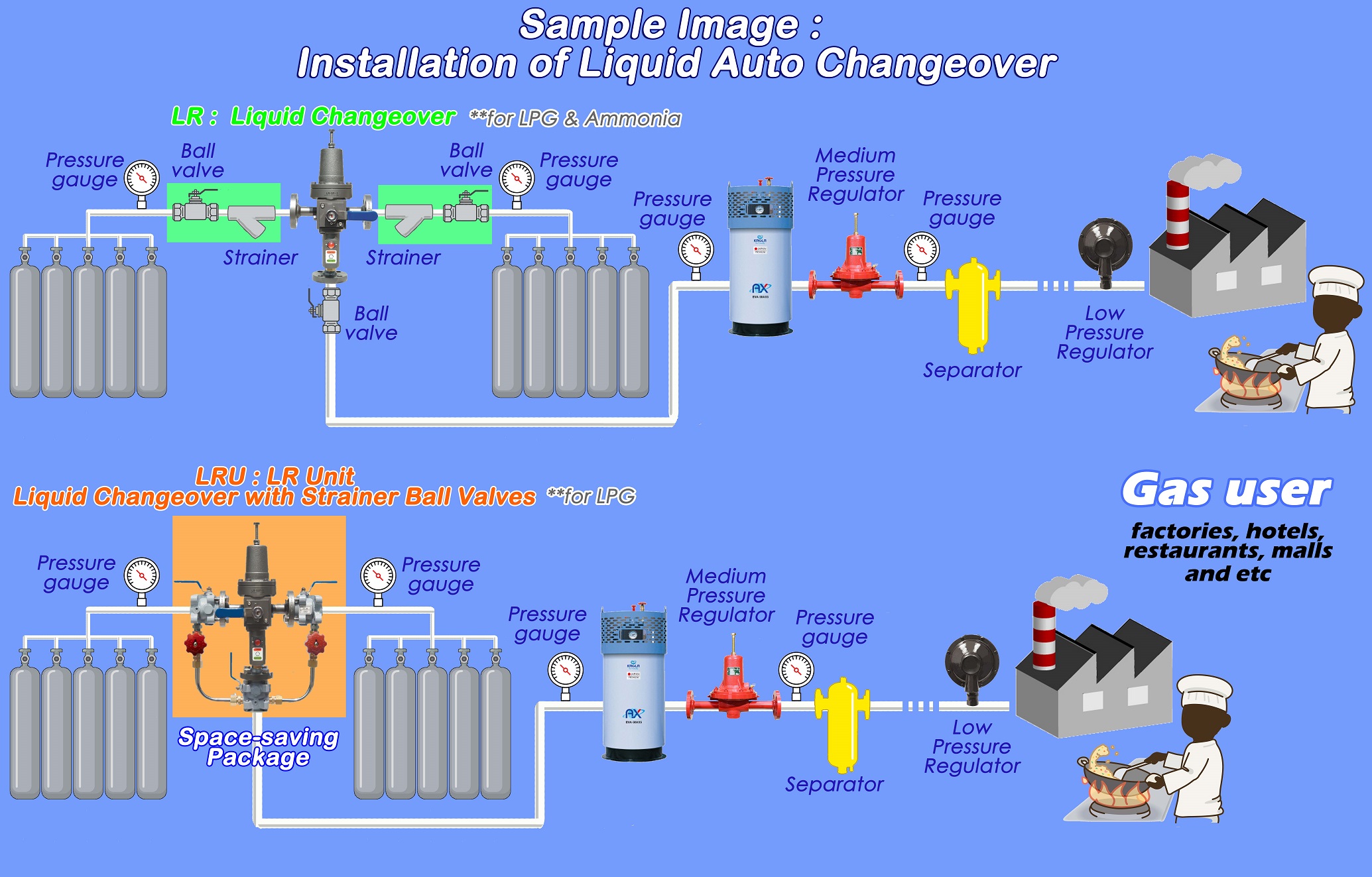

Sample installation image

Product Link-1: Kagla LR – Changeover body

Product Link-2: Medium pressure regulator Kagla KR series

Product Link-3: Electric water bath vaporizer Kagla AX5 series

Product Link-4: Electric water bath vaporizer Kagla CX series

Product Link-5: Dry-Electric vaporizer Kagla ADX series

Download

Contact us

Product inquiry

For inquiries about products and services, please use the inquiry form.