AX5 : Electric Water Bath type LPG vaporizer (100-500kg/h)

- Electric

- Hot water

- Steam

- Electric Water Bath type

- Capacity : 100 – 500 kg/h

- External Control Panel

- Float Valve safety feature

*Our Patented Technology - Explosion-proof : Flameproof / Intrisic safety

- Ex d ia II B T4 Gb / Class-1, Division-1

Idioma : English / Español

Advantages of Electric Water Bath type LPG vaporizer

Advantages of Electric Water Bath type vaporizer is its controllability, vaporization stability and safety.

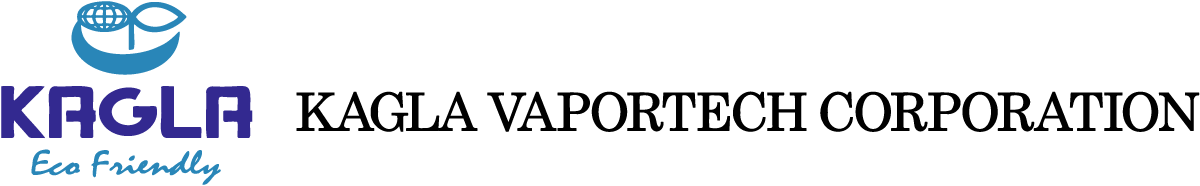

Electric heater warms the water in the bath. And this hot water indirectly heats the liquid LPG running through the heat exchanger tube.

As the heat source is hot water with a gradual temperature change, the vaporization ability is stable and controllable.

And even if there is a problem with the heat source, the vaporization ability can be exerted while the water is warm.

- Water temperature controlled between 75-85℃

- Spiral shape heat exchanger tube for smooth and stable vaporization

- Patented technology of Float Valve + Magnet system to prevent liquid carry over

- External Electrical Control panel for monitoring and Self-Diagnosis function

As the Liquid LPG (Propane) is heated indirectly by the hot water, it is safer than Direct Fire type vaporizers.

In some countries with specific gas regulations, Electric Water Bath type can be installed much closer to the tank / cylinders.

And its operation is noiseless.

Suitable applications : All Industrial and Commercial applications

- Shopping malls, Restaurants, hotels, applications in the residential areas…

- Factory holding combustibles and explosives (e.g. Paper factories, Gun powder factories…)

- Agribusiness operations (Grain dryer, Poultry farm heating and more)

- Residential / office heating (boilers and etc)

- Metallurgy purpose (e.g. Oxygen removal during copper smelting)

Features

ADVANCED SAFETY MECHANISM

- FLOAT VALVE with built-in magnet (KAGLA’s Patented Technology) prevents LPG liquid carryover.

**1 Please refer operation principle in the picture below. - WATER LEVEL SWITCH and SAFETY THERMOSTAT prevents over-heating of water bath

USER FRIENDLY INTERFACE

- Multi function electric control panel with digital indicator equipped.

- **2 See below for more details

SPACE SAVING COMPACT BODY

- Compact body size with Maximum Function designed upon long term experience of KAGLA since 1958.

EASY MAINTENANCE STRUCTURE

- Head cover of AX5 is removable for easy maintenance and overhaul.

WIDE RANGE OF SELECTIONS

- 5 different vaporization capacity models from 100kg/hr to 500kg/hr. (50kg/hr also available upon request)

DRAINAGE MEASURE

- Structure designed to minimize drainage to accumulate inside.

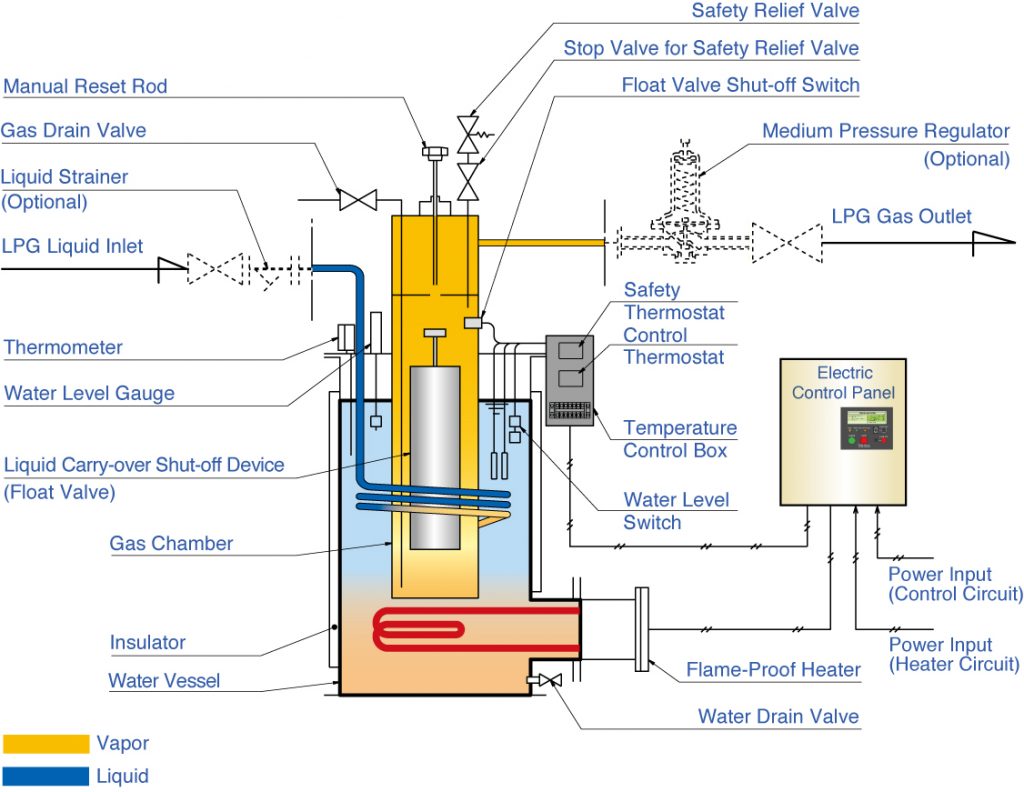

Vaporization mechanism of KAGLA Electric Water Bath type vaporizers

Electric Water Bath type vaporizer AX5 has Water Bath with Electric heater and the heat exchanger tube submurged in the water bath. The water temperature is controlled between 75-85℃ for stable vaporization.

When in operation, Liquid LPG (propane) goes into the heat exchanger tube from storage tank.

While the liquid goes through this tube, LPG liquid is vaporized by heat exchange with hot water in the bath and comes into the gas chamber.

And then it flows to the outlet for gas consumption.

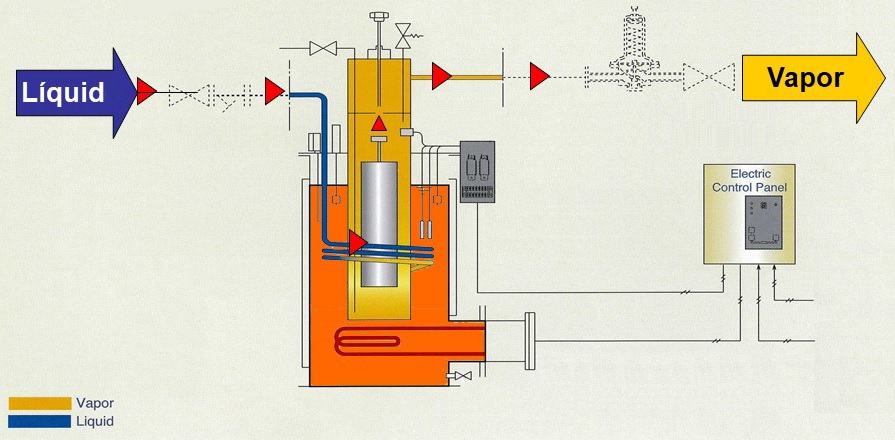

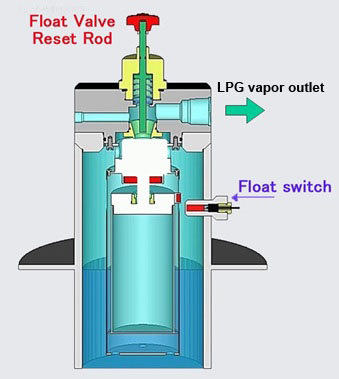

Function of Float Valve system (**1) – KAGLA patented technology

FLOAT VALVE is a safety function to prevent LPG liquid carryover to the downstream.

1) Float Valve shut off mechanism

Float Valve is a safety mechanism to prevent Liquid Carryover to the downstream.

When the gas consumption exceeds the vaporization capacity of the vaporizer, vaporization of LPG liquid may not catch up with gas consumption by the combustion equipment.

In this case, the non-vaporized liquid LPG will come into the gas chamber.

Then KAGLA Float Valve inside the gas chamber will be lifted upwards by the liquid and shut off the valve tightly with magnet connection.

Due to the phenomenon that the liquid pushes up the float, the gas chamber outlet is closed by the valve at the top of the float and prevent the LPG liquid from flowing to the downstream. Since it does not require external power sources such as electricity or pilot air, it is a system that operates reliably under all circumstances.

It also works in cases such as electric blackout, heater disconnection and others.

- It is a normal operation state where the hot water temperature is appropriate and heat exchange with the LPG liquid is properly performed. Since there is only LPG vapor in the gas chamber, the float is seated at the bottom position and thus the float valve is open.

- When the temperature of hot water drops and heat exchange does not occur properly, unvaporized LPG liquid flows into the chamber. Then the liquid accumulated in the chamber pushes the float valve upwards.

- If gas consumption continues in this state, the float valve will be forcibly closed by the powerful magnet placed on the top of the float valve.The flow switch mouto reduce the internal pressurented on the side of the chamber detects that the float valve is closed, and the error code No. 3 is displayed on the control panel.

2) Procedure to reset the float valve shutoff

- Refer to the display on the control panel to identify the cause of the float valve closure and eliminate the problem.

- Turn on the vaporizer to energize electric heater and warm the water in the bath.

- Close the liquid inlet and gas outlet valves.

- To reduce the internal pressure, open the drain valve slowly to release the LPG in the chamber and heat exchanger.

- When the water temperature reaches 75℃, open the valves and push down the reset rod to release the float valve closure.

Since a strong magnet holds the valve, some force is required to push the rod down.

If the reset rod cannot be pushed in at all, there may be liquid remaining in the chamber.

Open the drain valve to release if necessary.

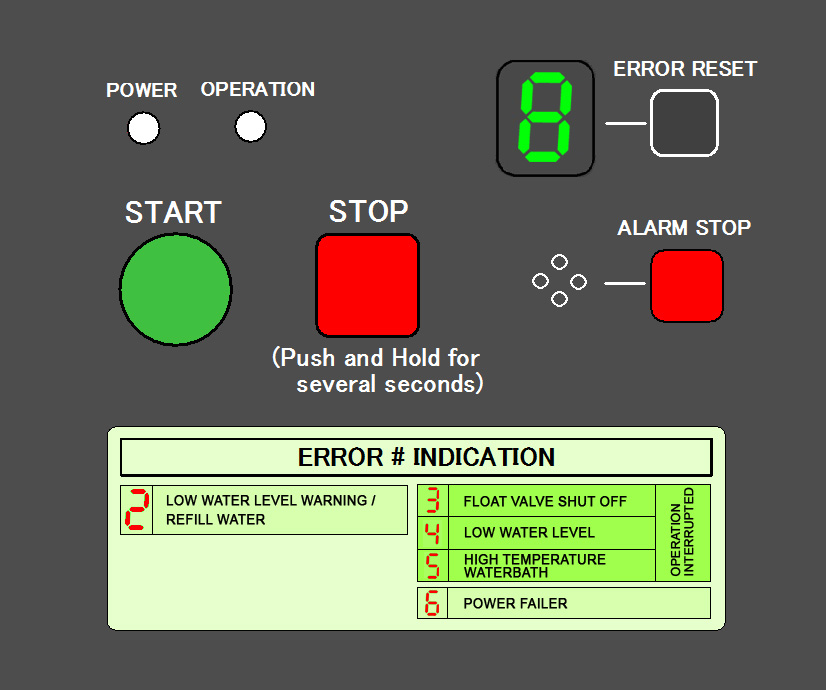

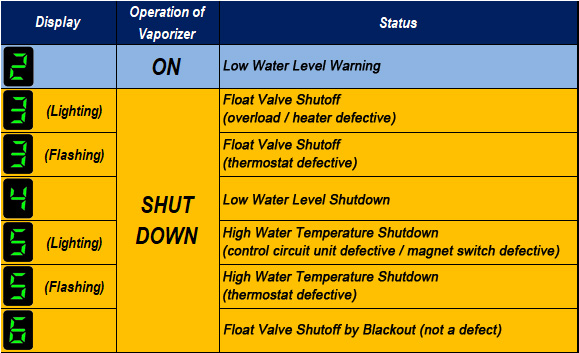

Self-diagnosis Function – Display on Electric Control Panel (**2. )

- Operation status of vaporizer can be monitored on the electric control panel from remote place.

- Combination of “lighting on” and “flashing on/off” indicate both the operation status and the cause of the problem.

- When the numbers 3 / 4 / 5 / 6 are displayed, operation of the vaporizer is interrupted.

Cause of the problem and Countermeasure

- No.2 displayed : Low Water Warning.

Detects and warns that the water level is falling. Add water to the water vessel.

*The operation of the vaporizer does not stop at the warning stage. - No.3 displayed (lighting) : Float Valve Shutoff (overload / heater defective).

Float Valve Shutoff

(caused by:i)overload / heater defective or ii)heater disconnection)

i) Do not consume gas exceeding the vaporization capacity of the vaporizer. Please change to a vaporizer with higher vaporization capacity or add another vaporizer to cover the shortage.

ii) Check the three-phase power supply of the heater(s). - No.4 displayed : Low Water Level Shutdown

If the water is not filled in when the water level warning (No.2) was displayed and the water level drops further, the vaporizer will shut down.

Add water to the water vessel and restart. - No.5 displayed (lighting) : High Water Temperature Shutdown

(control circuit defective / magnet switch welded)

Vaporizer shutdown due to abnormal temperature (water temperature 90℃) detection.

Control circuit failure or magnet switch welding (need part replacement). - No.5 displayed (flashing) : High Water Temperature Shutdown (thermostat defective)

Vaporizer shutdown due to abnormal temperature (water temperature 90℃) detection.

Thermostat failure (need part replacement). - No.6 displayed : Float Valve Shutoff by blackout (not a defect)

Float Valve Shutoff (caused by: Blackout – water temperature drops)

After the power is restored, restart the vaporizer, vaporize the liquid in the chamber, release the pressure in the chamber / heat exchanger, and then reset the float to restore the gas supply.

Specification

| MODEL | EV-50AX5 | EV-100AX5 | EV-150AX5 | EV-200AX5 | EV-300AX5 | EV-500AX5 | |

|---|---|---|---|---|---|---|---|

| Vaporization Capacity | kg/hr | 50 | 100 | 150 | 200 | 300 | 500 |

| U.S Gal/hr※ | 25 | 50 | 75 | 100 | 150 | 250 | |

| lb/hr | 110 | 220 | 330 | 440 | 660 | 1100 | |

| Water Bath Capacity | liters | 50 | 50 | 95 | 120 | 130 | 275 |

| Heat Exchanger Design Pressure | kg/cm2 | 18 | |||||

| psig | 257 | ||||||

| MPa | 1.77 | ||||||

| Liquid inlet bore | Rc3/4 | Rc1 | |||||

| Gas outlet bore | Rc1 | Rc1・1/4 | |||||

| Hydrostatic Test Pressure | kg/cm2 | 27 | |||||

| psig | 386 | ||||||

| MPa | 2.66 | ||||||

| Relief Valve Setting Pressure | kg/cm2 | 17.5 | |||||

| psig | 250 | ||||||

| MPa | 1.72 | ||||||

| Flame-Proof Electric Heater | kW | 8 | 14 | 21 | 28 | 42 | 63 |

| (14kWx2) | (21kWx2) | (21kWx3) | |||||

| Electric Requirement | Heater | 200/220/380/415/440/460V,3-Phase | |||||

| Control Circuit | 220V,1-Phase | ||||||

| Dimension(mm) | Width | 420 | 420 | 480 | 520 | 520 | 670 |

| Depth | 691 | 649 | 689 | 739 | 739 | 854 | |

| Height | 857 | 857 | 1058 | 1098 | 1158 | 1387 | |

| Vaporizer Control Panel Dimensions(mm) | Width | 300 | 450 | ||||

| Depth | 150 | 250 | |||||

| Height | 400 | 500 | |||||

| Weight | kg | 110 | 110 | 140 | 170 | 190 | 390 |

| Ib | 245 | 245 | 310 | 375 | 420 | 860 | |

| Design Standard Approval | Explosion-Proof Construction / NEPSI (National Supervision and Inspection Center for Explosion Protection and Safety Instrumentation) |

||||||

- * When gas composition is Propane50:Butane50 / outside temperature is 25℃

Heat Source : Hot water circulation / Steam heating type also available upon inquiries

Attenttion

- 50kg/hr model also available upon request

- The control panel is provided together with vaporizer

- Worldwide voltage available

Heater : 200 / 220 / 380 / 415 / 440 / 460V

Control circuit : 220V - Ambient temperature 0℃ ~ 40℃

- Gas composition : Propane 30% / Butane 70% ~ Propane 100% / Butane 0%

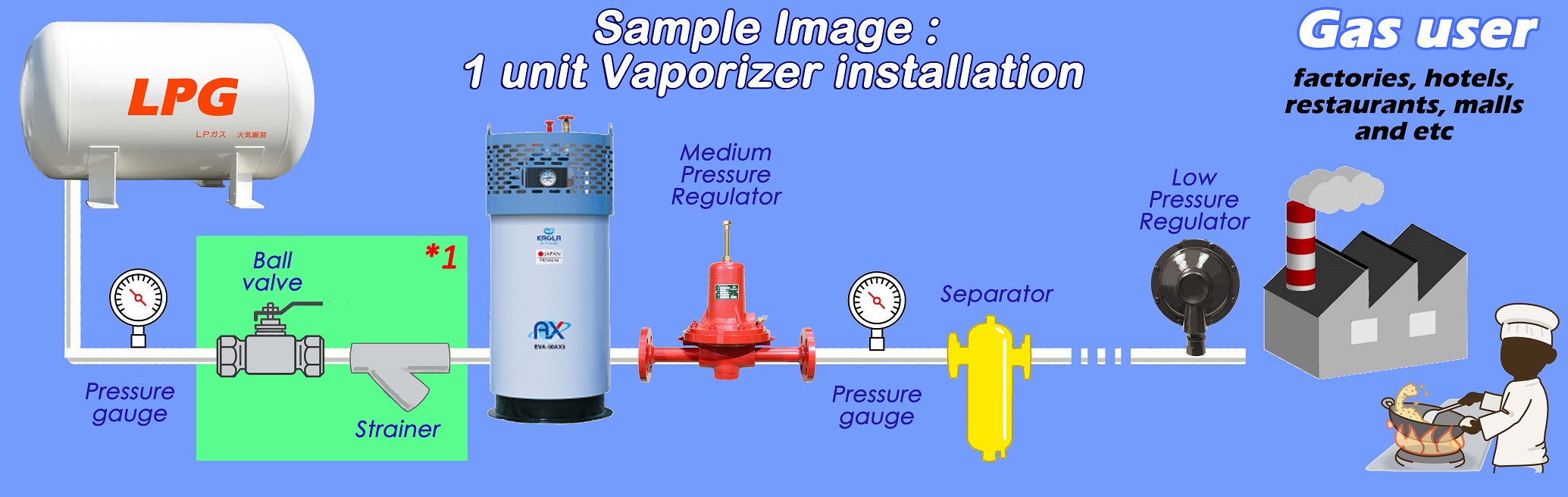

Sample installation image

Product Link-1: Space saving product Kagla PUREFLOW – Ball valve with built-in Strainer (*1)

Product Link-2: Medium pressure regulator Kagla KR series

Download

Contact us

Product inquiry

For inquiries about products and services, please use the inquiry form.