What is LPG? Why use Vaporizer?

Idioma : English / Español

Related links

1. What is LPG? – Basic knowledge

LPG (Propane) is widely recognized as Environmentally friendly / Eco-friendly fuel because it emits less carbon dioxide, which causes global warming, compared to other fossil fuels. Needless to compare with others such as firewood and coal. Also, since it contains no nitrogen and almost no sulfur, it is effective energy as a measure against SOx (sulfur oxides) and NOx (nitrogen oxides). Similar profile is seen with city gas (natural gas). And thus these 2, LPG (Liquefied Petroleum Gas) and NG (Natural Gas), can be considered among the best human friendly fuel of the day. In many countries, people use natural gas (or piped gas) as fuel for cooking and heating. And in some areas, LPG (Propane) plays that role.

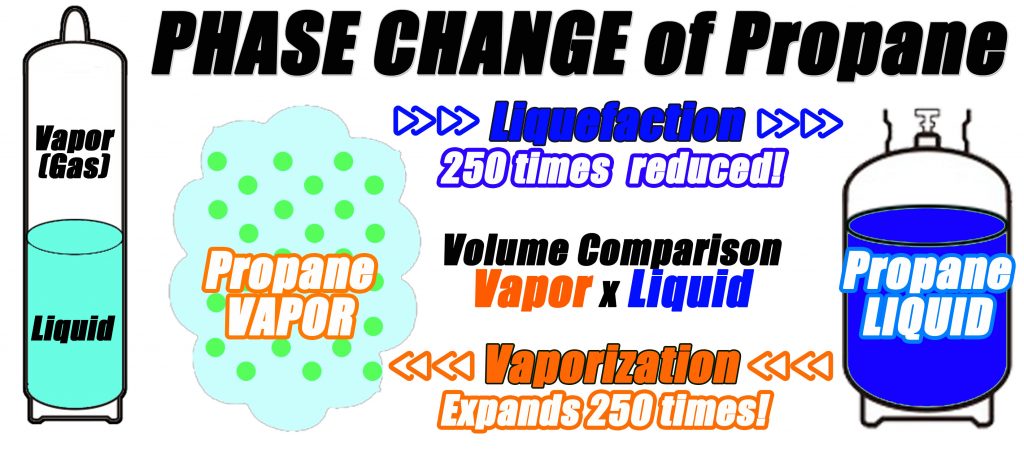

At standard pressure and temperature, propane exists as a gaseous fuel. But it liquefies at minus 42°C, and its volume in liquid state is 250 times reduced from its natural state. Natural gas liquefies at much lower temperature and thus Propane is easier to liquefy for transport in cylinders and stored in storage tanks. This property of propane allows people who have difficulty accessing NG networks to use fuel gas by storing liquefied propane within their premises.

Propane is valued in some cases such as natural disaster for its flexibility. For instance, in case heavy earthquake may destroy public infrastructure. As Natural gas is supplied to the users by gas piping network, if the piping may get serious damage, it will require much time to recover the gas supply. While on the other hand, Propane is supplied individually by cylinders and storage tank. Recovery is much easier because you can do at individual level. This was seen in Japan at big earthquake time in year 2011. History talks! The same applies in the cases of NG supply problems. And thus propane is often stored as back-up energy even at natural gas supply area.

2. Natural Vaporization

Propane exists as a gaseous fuel at standard pressure and temperature as explained earlier. By pressuring the gas and lowering the temperature, it is transformed into liquid state, Liquefied Petroleum Gas (LPG). However, your equipment burns vapor, not the liquid of course. And thus the propane as fuel must reach your consuming equipment in gaseous state. At the standard atmospheric pressure, with a boiling point of −42 °C (−44 °F), propane is naturally vaporized by its own while exchanging heat. This Phase-Change from liquid to vapor is called Natural Vaporization. This is the essential process when you consume propane with your equipment. When something is transformed, it requires energy. In the case of propane vaporization, it requires heat. Thus Vaporization takes place by Heat-Exchange. 2 factors effects rate of natural vaporization in your tank. Those are ambient temperature and size of the tank (surface exposed to the ambient heat). And therefore, maximum volume of natural vaporization has its limits upon these factors.

3. Vaporization not stable? Condensation on tanks / cylinders?

VAPORIZER is a solution!!

While the natural vaporization rate has its limits, if you continue consuming gas beyond vaporization capacity, your equipment may be shut down. And thus it interrupts continuous and steady operation to run your equipment. Take a look at your storage tank. If you see frost at the bottom of the tank, it is telling you that the consumption is beyond natural vaporization capacity. There are following 2 solutions to increase natural vaporization rate.

- Increase the tank size or add more tanks.

- Keep the tank filled all the time to increase the surface of heat exchange.

But unfortunately, these are not always good solutions. If the situation (codes, laws, space, etc…) doesn’t allow you to add more tanks, tank replacement cannot be your option. And even if it is possible, that will cost a lot. Frequent refills will also make operation costly.

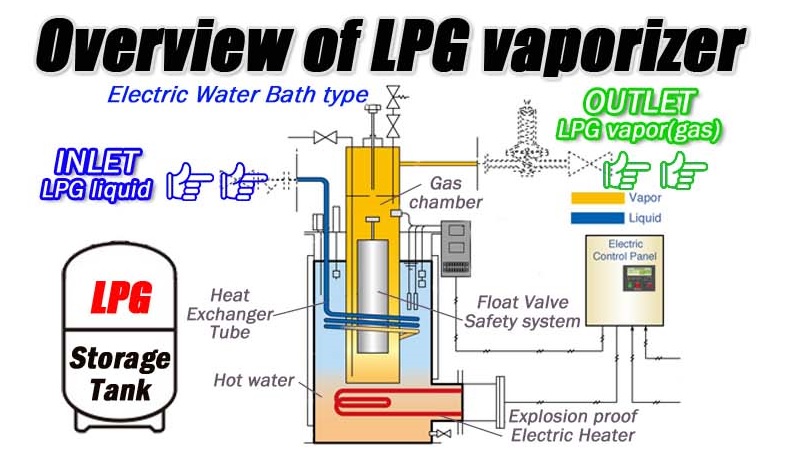

In such cases, installation of VAPORIZER would be fundamental solution. VAPORIZER is a kind of boiler to increase the heat exchange and assist LPG vaporization. LPG enters the vaporizer as a liquid and exits as a gas, just like we see with natural vaporization. The big difference is that vaporizers has function to add artificial heat to realize more stable and larger vaporization capacity. As it is creating artificial heat by its own, it demonstrate stable vaporization performance regardless of outside temperature. And as the vaporizer itself is the heat exchanger, size and numbers of tanks is not a factor to control vaporization rate. Therefore, you don’t need to replace to bigger tank or add more tanks. As you can increase the gas supply volume with existing tanks, you can save space for construction.

And there’s one more issue to be considered – LPG composition. LPG is a mixed gas and its main components are Propane and Butane. Depending on the area and usage, Propane-Butane composition differs. For instance, LPG in Japan is 100% Propane. But in other countries, often Propane rate is 60-70%. Butane is richer than Propane in its calorific value. But its boiling point is −5 °C, which is much higher than Propane. And therefore, Butane mixed LPG requires higher temperature for vaporization. When in natural vaporization from tank, as you consume vapor LPG, Butane is likely to remain more in tank and thus the gas composition may be changed. This nature also changes natural vaporization rate. But in the case of using vaporizer, as it takes liquid LPG directly and vaporize it by force with higher heat exchange, it vaporize both Propane and Butane evenly. And thus the Gas composition remains the same.

| Gas | Formula | Formula | Calorific value |

|---|---|---|---|

| Propane | C3H8 | -42℃ | 24,000kcal/m3 |

| Butane | C4H10 | -0.5℃ | 31,000kcal/m3 |

Finally, vaporizer contribute to minimize the drainage (heavy-ends). In natural vaporization, the vapor goes upward and liquid remain bottom of the tank. And therefore, drainage is likely to accumulate at the bottom of the tank. You need to take measure to remove this sometimes. But if you use vaporizer, this will be lesser because the vaporizer takes the liquid directly from downward.

<Summary : Advantages of using vaporizers…>

- It can cover a large amount of gas consumption without adding storage tanks.

- As no additional tanks are required, you can save space and cost.

- It realizes stable supply regardless of outside temperature and tank size.

- LPG composition would not change as it directly vaporize LPG liquid.

- Drainage (heavy-ends) does not easily accumulate at the bottom of the tank as it directly vaporize LPG liquid.

- You can select the best vaporization capacity model to match your consumption volume from various choices.

4. Type of vaporizers

There are several types of vaporizers with different heat source that you can select. In Japan, where the land is small and the residential and industrial/commercial areas tend to be adjacent to each other, very strict rules are set regarding gas usage, and safety is considered to be the most important issue in operation. Due to safety rules, direct-fire vaporizers that use fire are rarely used in Japan. Instead, electric vaporizers that can ensure better safety are the mainstream. KAGLA mainly manufactures electric, steam, and hot water circulation vaporizers that demonstrate safe and reliable operation. Of course, all products are Explosion-proof structure. Since they can be installed closer to the tank than Direct Fire, they also contributes to space saving construction.

①Electric Water Bath vaporizer

Electric heater warms the water in the bath. And this hot water indirectly heats the liquid LPG running through the heat exchanger. As the heat source is hot water with a gradual temperature change, the vaporization ability is stable and controllable. And even if there is a problem with the heat source, the vaporization ability can be exerted while the water is warm.

②Dry Electric Type vaporizer

Dry electric type is adopted for the compact vaporizers for space saving. Electric heater warms the liquid LPG in the heat exchanger. Since it is a single-phase power supply specification, construction of a three-phase power supply facility is not required and thus installation is easy. Simple and maintenance easy structure.

③Steam Heating Water Bath Type vaporizer

The steam heater is equipped instead of the electric heater. The existing boiler can be used to run the vaporizer. The basic structure including the safety mechanism is the same as the electric water bath type. As the heat source is hot water with a gradual temperature change, the vaporization ability is stable and controllable. And even if there is a problem with the heat source, the vaporization ability can be exerted while the water is warm. No power supply is required as the hot water temperature is controlled by steam.

④Hot Water Circulation Type vaporizer

It is a vaporizer with a simple structure that circulates hot water from a water boiler as a heat source. You can make use of the existing hot water boiler. The basic structure including the safety mechanism is the same as the electric water bath type. As the heat source is hot water with a gradual temperature change, the vaporization ability is stable and controllable. And even if there is a problem with the heat source, the vaporization ability can be exerted while the water is warm. No power supply is required as the hot water temperature is controlled by water boiler.

⑤SNG vaporizer (Natural Gas Back Up Mixer)

Since the calorific value of natural gas is much lower than that of LPG, ordinary combustion equipment for natural gas cannot be operated with LPG. The SNG vaporizer solves this problem and makes it possible to operate natural gas equipment using LPG as an alternative fuel. SNG (Synthetic Natural Gas) substitutes natural gas in case of supply problem. This product is compactly packaged on a skid that combines an LPG vaporizer with an air mixing device. By diluting LPG, a mixed gas (SNG) close to the calorific value of natural gas is generated and used as an alternative fuel for natural gas equipment. KAGLA’s SNG vaporizer uses a Venturi type structure that takes in air only when LPG vapor is injected. As this mechanism does not generate mixed gas in the explosion range, it is excellent in safety. It is often used as a backup facility in areas where the natural gas supply is unstable. Even if a problem occurs in the supply of natural gas, the operation is automatically switched to SNG vaporizer by sensing the pressure drop. And thus you can continue operation without stopping the equipment by consuming SNG.

⑥NH3 (Ammonia) vaporizer

Ammonia is a compound of Nitrogen and Hydrogen with the formula NH3. NH3 boils at −33.34 °C (−28.012 °F) at a pressure of one atmosphere. It is normally stored in cylinder or tank in liquid state and vaporized to gaseous state when in use. Natural vaporization is generally used, but for some specific usage, ammonia vaporizer installation is highly recommended. Metal Nitriding (heat treatment) is among such usage. Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. This is treated against many of mechanical parts (cars and other machines) such as gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, die-casting tools, forging dies, extrusion dies, firearm components, injectors, plastic-mold tools and etc. The purpose of nitriding is to increase the surface hardness of the steel and improve its wearing properties. And this is one of the important processing operation for these types of metal parts. For nitriding, unlike LPG, NH3 (ammonia) gas is not burnt. It is used in gaseous state as nitrogen rich gas, to prevent oxidation while in heat treatment. When ammonia comes into contact with the heated work piece it dissociates into nitrogen and hydrogen. The nitrogen then diffuses onto the surface of the material creating a nitride layer. This is a kind of sensitive work and thus the ammonia gas should be under good control. Therefore, we recommend installation of Vaporizer for safe and stable supply of ammonia vapor. Ammonia is a corrosive gas, and thus corrosion-resistant materials are required to be equipped in important parts of vaporizers and connected devices. For this reason, KAGLA has a series of equipment such as valves, regulators, and liquid changeover devices, with a vaporizer at the top, designed to be used exclusively for Ammonia.

KAGLA’s Japan domestic products

Introducing some of Japan domestic products of KAGLA. We also have varieties of unique products other than LPG vaporizers.